Firstly, we’ll discuss where and how the clothing will be worn to help us select the best fabric bunches for whatever you wish to have made. This meeting can take place at our Savile Row shop, at your home, office or during one of our trunk shows.

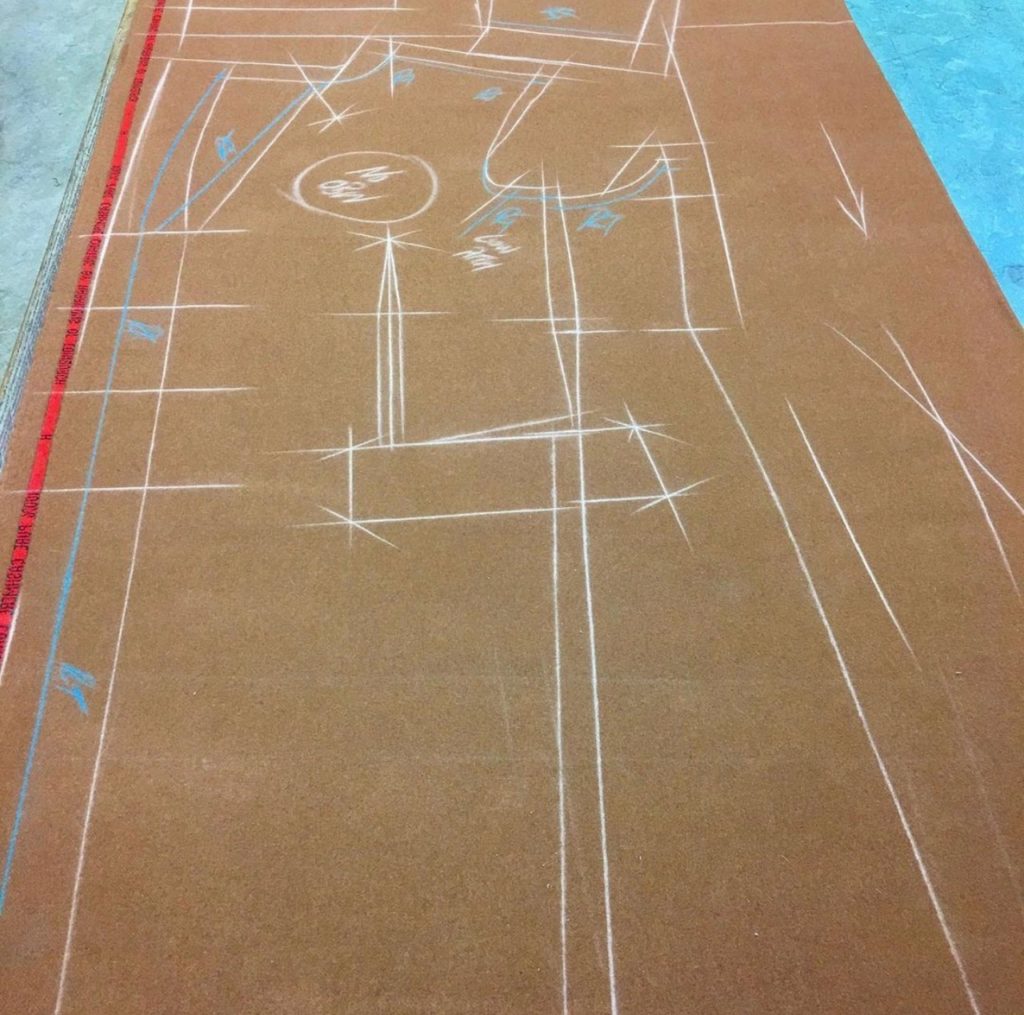

Secondly, we’ll take your measurements. Approximately 35 measures and figuration notes, as well as photographs are taken.